What do you use soft soldering for?

Soft soldering is used on metal types such as Brass, Copper, Zinc, Tin Plate, Soft Steel (Not stainless steel), and Nickel Silver.

Solder – The joining Material.

Solders come various types fro rolls of solder to easy flow and Low Melt types designed for softer metals such as white metal*.

I use a 60/40 standard solder for most of my work, as this has a 60% lead to 40% tin mix, and I find this flows very well for my brass and other metals I use when building my models.

For electrical connections use Non Corrosive Resin Cored Solder.

*When using white metal parts its recommended that you use a soldering iron with a temperature control so adjustments can be made to the soldering iron.

Fluxes

The purpose of flux is to help the flow of solder between the two parts and bond them together.

There are various brands and types including some specialist ones for different metal types.

Soldering Irons

These come in various power ratings, and dependant on the job size will determine the power rating required. For most model making and electrical projects an iron of between 25 watts and 40 watts will be suitable.

Preparation of the tip is vital: with Tin Plated Tips (Weller) clean with sandpaper or a file. Iron Plated Tips (Antex) should only be wire brushed. When the tip is clean, dip in flux then apply a little solder to tin* the tip.

*Tinning – coating a base metal with a thin coat of solder

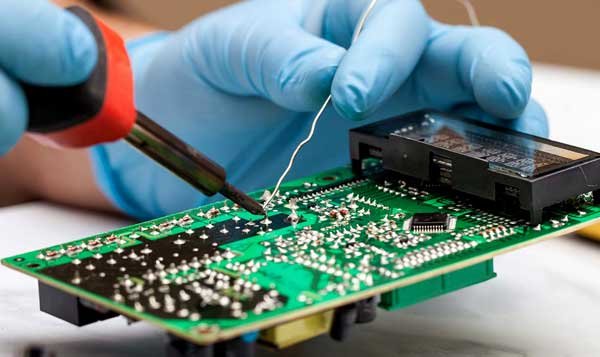

Soldering

Make sure that the joint surfaces are clean, then add flux and then solder using the iron so each joint surface has a layer of solder.

Put the joint together then apply the soldering iron tip to melt and unite the solder layers to make the joint.

On long joints, start at one end and work your way along rather than spot joint.

Safety

Make sure that your work area is clean, tidy, stable, and free from sources of ignition

Check that you’re working in a well-ventilated area with suitable fume extraction available

Always wear safety glasses, and use heatproof gloves for handling materials

Always return the iron to its cradle or stand when not in use – never lay it directly on a work surface, table or bench.

If you do suffer a burn, immediately hold it under cold running water for a minimum of 10-15 minutes before following any necessary first-aid procedures